Precision Laser Cutting

Excellent quality with a wide variety of metals

What is Laser Cutting Manufacturing?

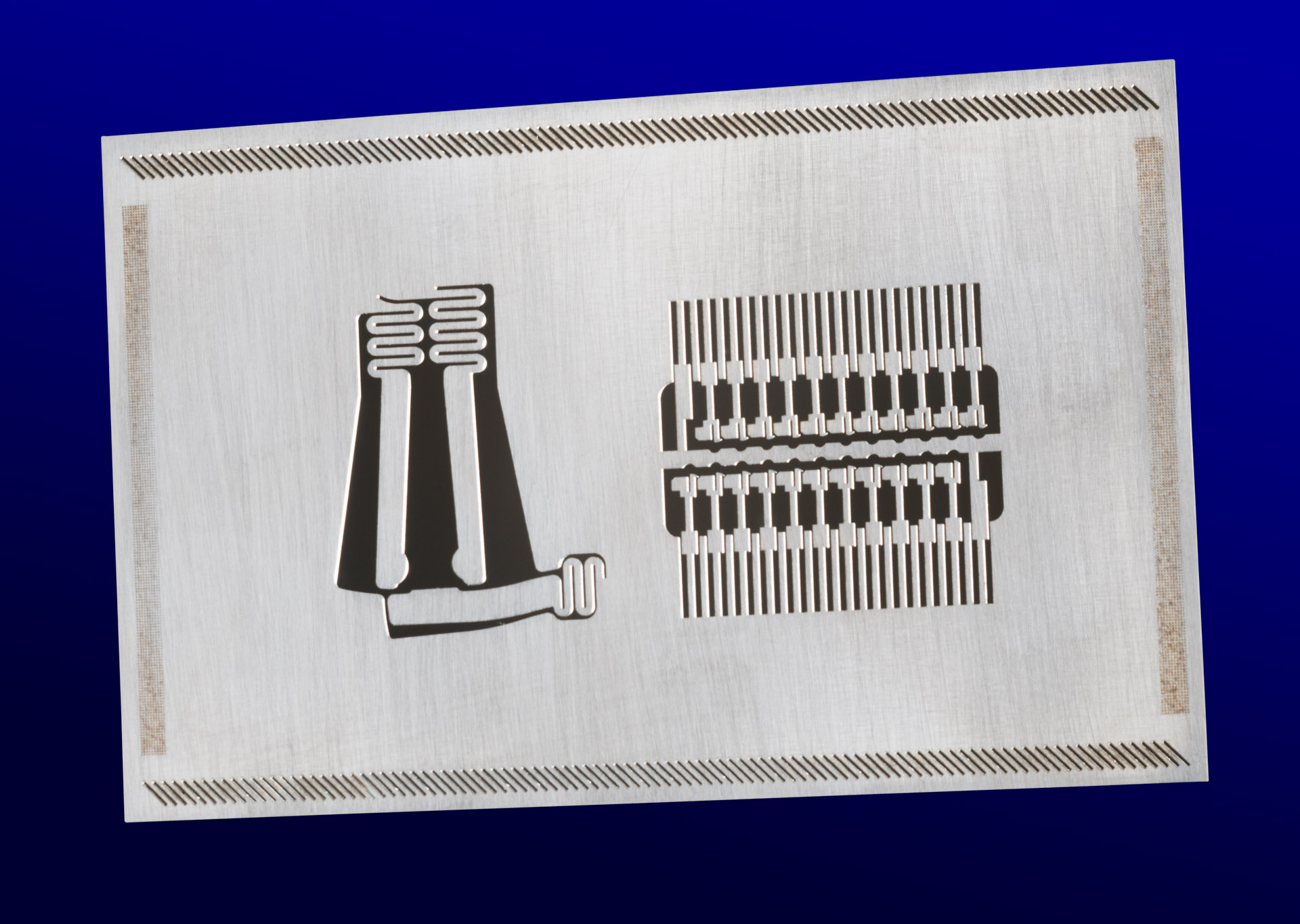

Thin Metal Parts has a wide range of state-of-the-art laser cutting capabilities, with both fiberoptic and UV laser tools. The computer-directed, custom-designed, fiber laser focuses a high-powered laser beam on the metal, which melts or burns away the excess until the desired part emerges. The UV laser utilizes UV light and has higher precision and better cutting effect than a traditional long-wavelength cutting machine for various materials. Laser cutting leaves a high-quality surface finish and can be used with a variety of metals and materials.

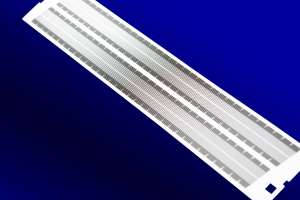

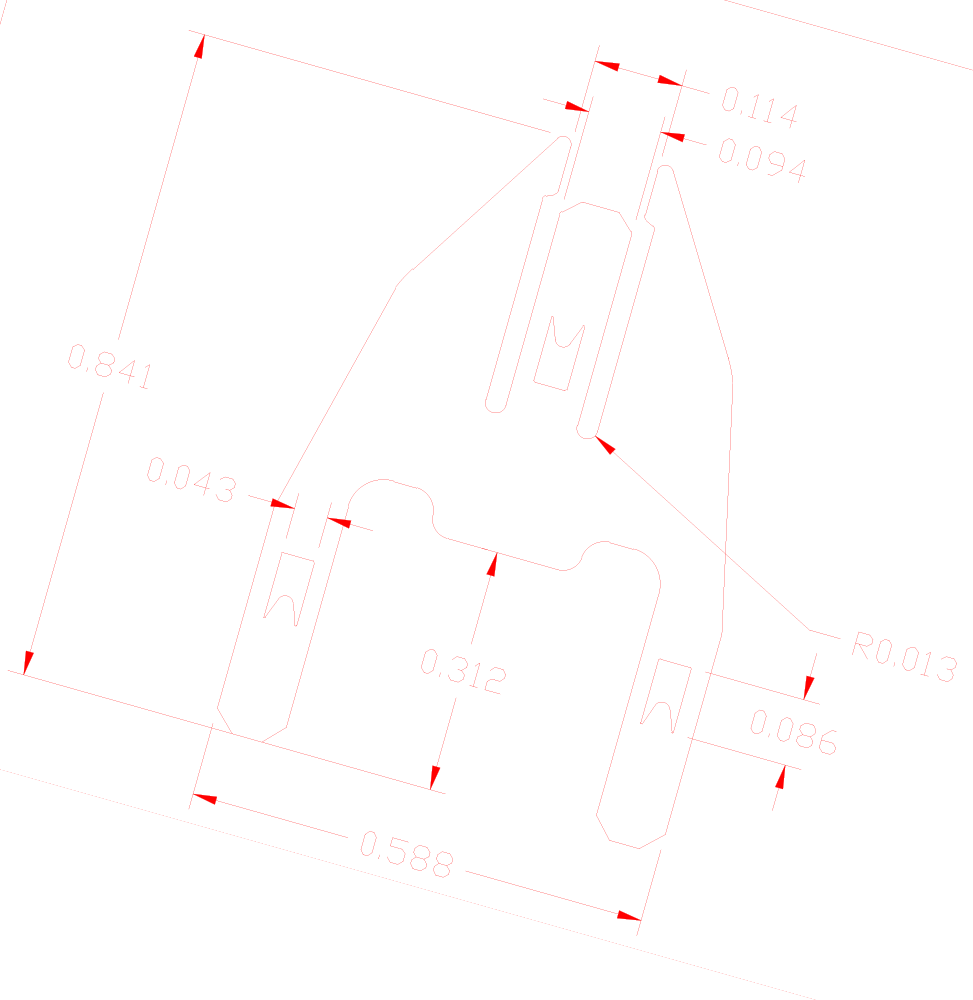

State of the art laser equipment allows Thin Metal Parts to achieve an outstanding combination of edge quality, tolerances, and feature sizes with openings as small as 15 microns.

Laser capabilities

Fiberoptic Laser

The fiberoptic laser can create precision edges without burs or heat. Fiberoptic laser-cut can be very useful for prototyping projects as it is an inexpensive, fast, and versatile tool.

Materials include most metals, except for aluminum, brass, and copper.

UV Laser

UV lasers have shorter wavelengths than the visible wavelength, which requires a very short, focused laser for a higher precision cut. In addition to the low work piece temperature, the high-energy photons that exist in ultraviolet light allow the UV laser to be used with non-metallic and other various materials. Source from stylecnc.com

The UV laser cuts metals, non-metallic insulating, and other lamination materials. The materials include but are not limited to most stainless steel, copper, brass, Kovar, nickel, aluminum, blue tempered steel, invar, Mylar, Kapton, and Nomex paper.

Learn more about UV Laser capabilities on Nonmetallic Insulating material

Learn more about Electric Motor Lamination

Advantages of Laser Cutting Fabrication

- Laser beam diameter is 25µm

- Excellent performance on metals not ideally suited for chemical etching, such as titanium and tungsten

- In-house engineering

- Tab-free designs available

- Relatively fast process

- May be combined with electroforming and chemical etching to produce highly complex designs

- Secondary forming available

- Thicknesses ranging from 25 to 635µm

- Some post-processing finishes may include: nickel, chrome, tin, zinc, titanium nitride, gold, black oxide and black chrome.

Why Choose Thin Metal Parts Manufacturing Services

- Made in the U.S.A. and done completely in-house: from the preliminary design of the project all the way through shipment, everything is completed in-house which means maintaining control of the project every step of the way.

- Cost Effective: A large inventory of numerous thicknesses and specifications to meet most demands is kept in stock.

- All CAD and manufacturing are done on site and in-house.

- Ability to ship fully custom pieces designed to exact specifications in a matter of days.

- Quick Turn Over: From conception to completion in less than a week in most cases.

- Expertise: Precision engineers are highly trained and maintain certification of the highest caliber.

- Versatility: Chemical Etching, Electroforming and Laser-Cutting can be used to create custom thin metal parts for any application ranging from highly technical medical or aerospace applications to decorative elements. In-House manufacturing allows for the capacity to do jobs of any scale, from prototypes through high-volume orders.

- Reliability: If any questions, complications, changes arise, the in–house design and manufacturing team is ready to make the necessary changes in order to get customers the precision pieces they deserve.

- Quality:

- ISO 9001:2015 certification documents processes and insures quality and precision.

- ITAR registration ensures traceability and documentation of all raw materials used in processing.

Hover to see closeup

Request Samples

Using three different technologies, custom metal parts can be built for thousands of applications for a large variety of industries. By combining multiple technology options, a hybrid precision part, unavailable anywhere else in the global marketplace, can be custom manufactured.

Thin Metal Parts regularly works with the aerospace, computer, and electronic industries to build custom precision parts used in industrial and consumer goods applications... parts such as metal encoder wheels, metal mesh, and print heads. In addition, custom parts are developed daily in research and development as the design/process engineer group teams with customers to develop prototypes and production items in medical, manufacturing, and scientific instrument sectors.

All products are custom manufactured to meet customer needs and specifications, including DFARS and RoHS compliance. These quick-turn, cost-effective, low tooling cost processes offer excellent production alternatives to traditional fabrication methods for metal parts in high volumes and prototyping.

Request samples

4733 Centennial Blvd.

Colorado Springs, CO 80919

Phone: 719.268.8300

Fax: 719.268.8399

E-mail: info@thinmetalparts.com