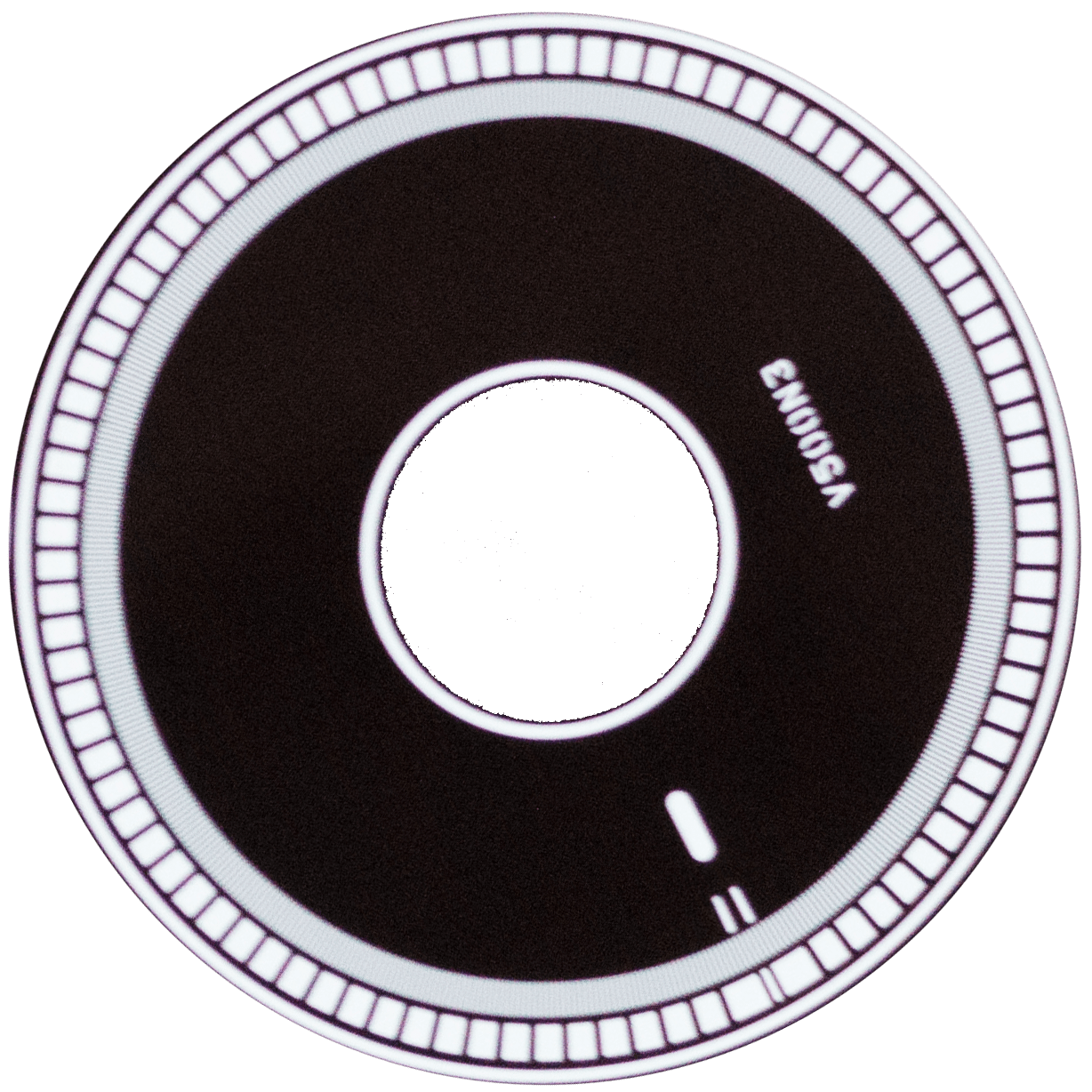

Encoder CodeWheels

Encoders for high-precision applications

Metal encoder wheels (codewheels) are designed for high-precision applications in incremental and absolute rotary encoders. The encoder wheels can be produced using any of the available processes at Thin Metal Parts, depending on resolution specifications. These include electroforming, chemical milling, laser cutting, and Mylar™ imaging. The products are corrosion resistant and offer superior stability in high-temperature and high-shock environments.

Advantages

- Resolution: Electroformed metal encoder wheels are available in resolutions previously unavailable in metal encoder wheel technology. Closer tolerances, greater design capability, and increased consistency are all attributes of our proprietary electroforming process.

- Flatness: The Thin metal Parts proprietary electroforming process reduces the amount of surface tension imposed on the metal encoder wheel, minimizing any possibility of warping.

- Cost: In most applications, metal encoder wheels offer an inexpensive alternative to glass encoder wheels without sacrificing quality.

- Dimensional stability: Temperature and humidity have virtually no impact on the metal encoder wheel. In addition, our metal encoder wheels can be used in high-shock environments with dependable results.

- Corrosion resistance: Our Thin Metal Parts 100% nickel encoder wheels provide excellent corrosion resistance.

- Multi-layer technology: Multi-layer options are available to maximize the encoder wheel stability and strength.

Thin Metal Parts provides code wheels for many industries, such as:

- Aerospace

- Electronics

- Industrial Automation

- Medical

Benefits of Codewheels Made with Electroforming

Thin Metal Parts is the industry leader in the manufacturing of encoders and code wheels. The proprietary nickel electroforming process creates the highest quality, most precise products available. Contact or call Thin Metal Parts at (719) 268-8300 for more information or to request samples of products.

Request Samples

Using multiple technologies, we can design and build metal parts for thousands of custom applications across many industries. A hybrid manufacturing approach and industry-leading expertise allows Thin Metal Parts to manufacture precision parts that are unavailable anywhere else in the world.

Our custom metal parts and components are used in a wide variety of industrial and consumer goods applications for many of the country’s leading companies. All customer needs and specifications, including DFARS and RoHS compliance, are respected during manufacturing to provide a dependable custom solution.

At Thin Metal parts, we pride ourselves not only on custom manufacturing but also superior customer service. Clients working with Thin Metal Parts can expect unmatched responsiveness, quick turnaround times, cost-effective options, and highly customizable flexible manufacturing across prototype, small run, and large volume production.