Electroforming

The ultimate in precision and tolerance

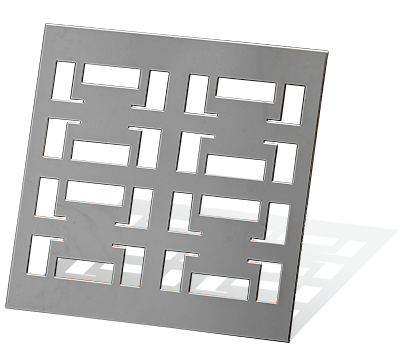

Precision Electroforming Fabrication

Electroforming is a metal fabrication process that creates precision metal components on an extremely delicate scale. It is a meticulous process renowned for its ability to create thin and exceedingly complex designs.

During electroforming, metal is actually “grown” in the shape of a photolithographic (“printed with light”) pattern. To create accurate designs on this scale, the patterns are rendered in an electrically conductive medium. Nickel “plates-up” around this pattern, generating a metal part with micro-precision.

The extensive testing and research performed by Thin Metal Parts have led to a proprietary electroforming production process that guarantees the highest caliber, consistent and stable thin metal pieces. Our Electroforming Company is the only one to provide this proprietary process, giving engineers the flexibility to produce electroformed pieces out of nickel capable of varying degrees of hardness, brightness, and malleability. The ground-breaking electroforming system guarantees consistent surface finish and dimensional stability on both sides of the part.

Why Choose Thin Metal Parts' Electroforming Process Services?

- Fast initial design time

- Cost effective

- Low-cost tooling completed in only a few hours

- Clean-room photolithographic area avoids degradation of the photolithographic process

- The highest standards of quality and precision are maintained

- Tab-Free and burr-free designs

- Collimated light exposure systems

- No visible grain direction

- Extremely tight tolerances of ±5 microns

- Surface finishes that are guaranteed to be consistent and allow the client choice of matte or mirror-like on one or both sides

- Capable of extremely complex designs (feature sizes as small as 15 microns on thicknesses ranging from 10-150 microns.)

- All projects are completely customized to precise specifications

- Quick turnaround time (just 4-6 days in most cases)

Applications

- Photosensitive drums in office equipment

- Wave guides

- Micro gears & springs

- Micro artificial organs

- Heat sinks

- Shuttle blades

- Decorative items

- Ink jet nozzles

- MEMS

- Micro relays

- Optical parts

- Bellows

- Fuel directors

- Micro sprockets

- Lead frames

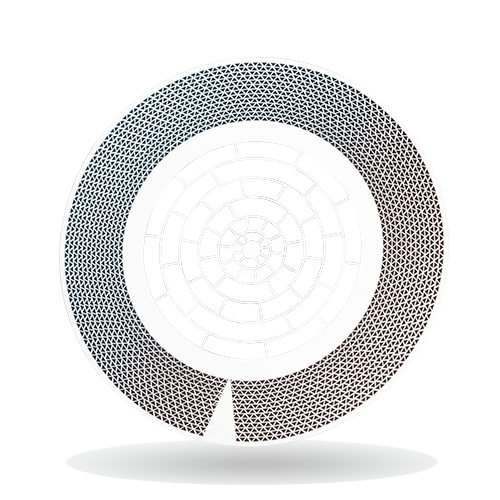

- Encoder discs

- Micro rotors & shuttles

- Name plates

- Flow sensors

- Micro valves

- Micro resonators

- Molds

- Diamond cutting

- Foundry patterns

- Stampers

- Press tools

- Dies

- Abrasive tools

- Textile printing screens

- Deposition masks

- Micro filters

- Electric razor screens

- Continuous porous substrate

- Electronic stencils and screens

- Sieves

- Wire cloth

- Nickel foil

Why Choose Thin Metal Parts

- Made in the U.S.A. and done completely in-house: from the preliminary design of the project all the way through shipment, everything is completed in-house which means maintaining control of the project every step of the way.

- Cost Effective:

- All the designing AND manufacturing are done on site and in-house

- Ability to ship fully custom pieces designed to exact specifications in a matter of days.

- Quick Turn Over: From conception to completion in less than a week in most cases.

- Expertise: Precision engineers are highly trained and maintain certification of the highest caliber.

- Versatility: Chemical Etching, Electroforming and Laser-Cutting can be used to create custom thin metal parts for any application ranging from highly technical medical or aerospace applications to decorative elements. In-House manufacturing allows for the capacity to do jobs of any scale, from prototypes through high-volume orders.

- Reliability: If any questions, complications, changes arise, the in–house design and manufacturing team is ready to make the necessary changes in order to get customers the precision pieces they deserve.

- Quality:

- ISO 9001:2015 certification documents processes and insures quality and precision.

- ITAR registration ensures traceability and documentation of all raw materials.

4733 Centennial Blvd.

Colorado Springs, CO 80919

Phone: 719.268.8300

Fax: 719.268.8399

E-mail: info@thinmetalparts.com