Custom Metal Mesh & Sieves

Metal Mesh & Sieves for Every Application

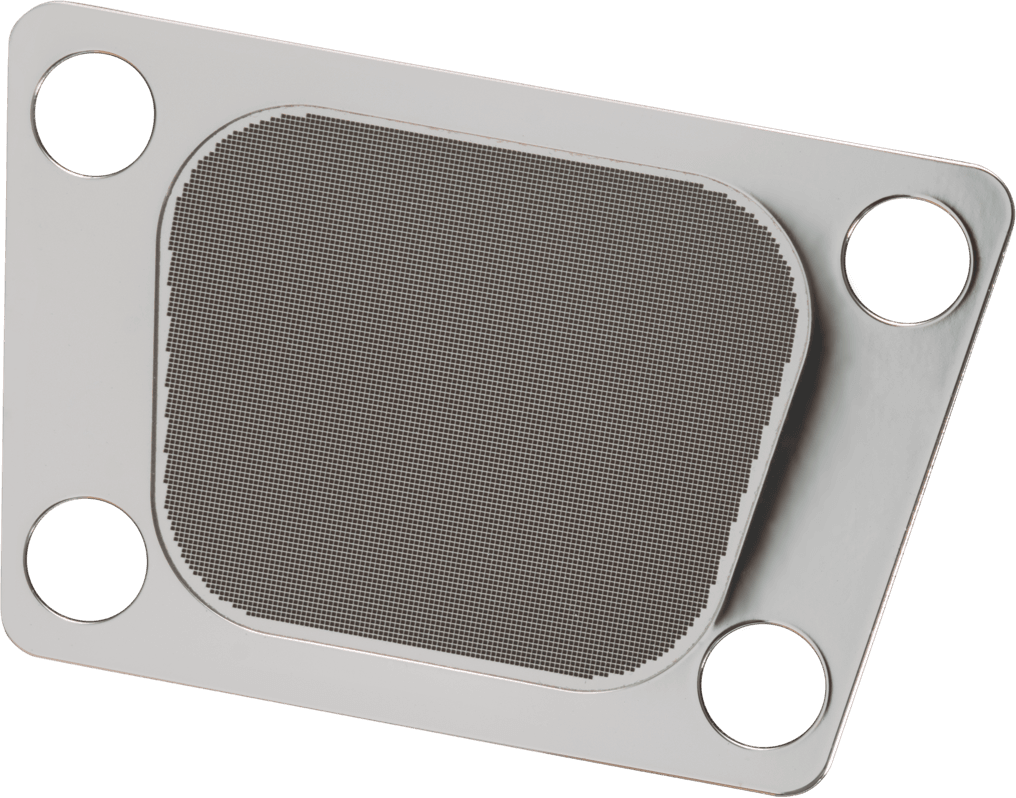

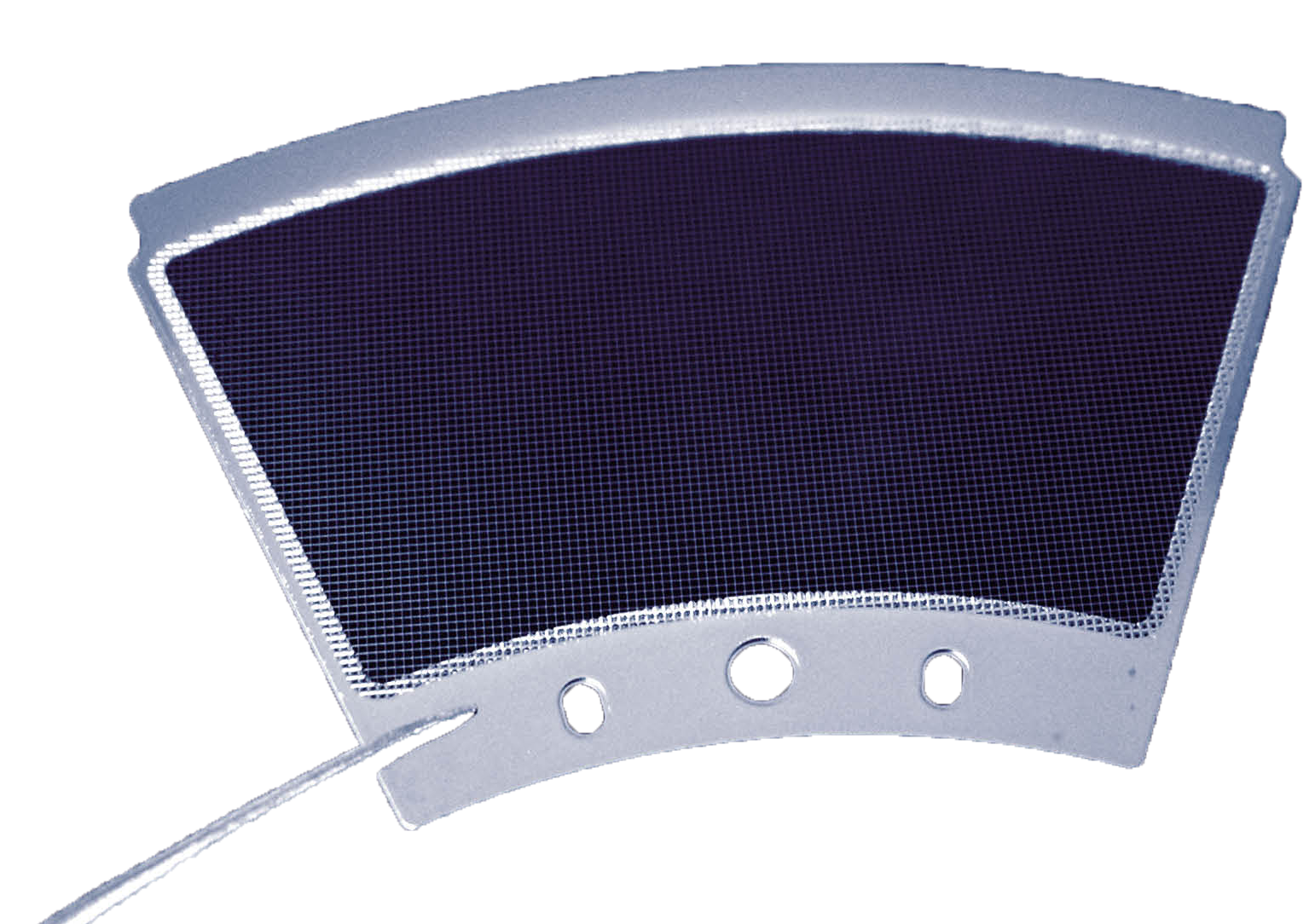

Thin Metal Parts, a top metal parts manufacturing company in Colorado, offers high-precision electroformed metal mesh, manufactured with a proprietary process. Electroformed mesh and metal sieves achieve the highest standards for optical light transmission (OLT), scientific devices, as well as for gas and liquid filtration applications.

Compared to woven mesh, Thin Metal Parts' non-woven metal mesh is all one solid piece with a smooth finish. Using electroforming technology, sieves (typically a round hole for filtration, or mesh (typically a square hole for filtration) can be created for many different applications.

Hover to see closeup

Advantages of Custom Metal Mesh

- Thickness: Mesh is available in a wide range of thicknesses to suit the design requirements of each specific application. When strength is a concern, this process produces a product at greater thicknesses than woven wire or even other electroforming techniques. Alternatively, electroformed mesh can be produced at very fine thicknesses down to 10 microns.

- Non-woven: Unlike woven wire mesh, electroformed mesh is a single, flat piece of metal. By eliminating the criss-cross wires, this mesh will not trap particles...making cleaning more efficient. Additionally, light transmission can be maintained within a ±2% transmission tolerance.

- Corrosion resistance: Produced from 100% pure nickel with no plating to wear off, electroformed custom metal mesh has natural corrosion resistance that will not diminish with time.

- Custom high-temperature option: Through a custom-developed process, electroformed mesh and metal sieves can withstand temperatures exceeding 500°C for decontamination and tensioning requirements.

- Custom manufacturing: Electroformed mesh by Thin Metal Parts is highly customizable by variations in wire width, hole size, thickness, hole shape, and overall shape. A nearly limitless number of product configurations are available. Furthermore, utilizcutting-edgeedge photolithography manufacturing techniques allows for customization to occur without long delays or increase in prices.

Light Transmission Control

Utilizing Thin Metal Parts' proprietary electorforming process, precise metal mesh and metal sieves that block up to 50% of light with a ±2% light transmission control tolerance can be created. Every mesh and sieve application can be achieved. Contact or call Thin Metal Parts at (719) 268-8300 to learn more.

Request Samples

Using three different technologies, custom metal parts can be built for thousands of applications for a large variety of industries. By combining multiple technology options, a hybrid precision part, unavailable anywhere else in the global marketplace, can be custom manufactured.

Thin Metal Parts regularly works with the aerospace, computer, and electronic industries to build custom precision parts used in industrial and consumer goods applications... parts such as metal encoder wheels, metal mesh, metal sieves, and print heads. In addition, custom parts are developed daily in research and development as the design/process engineer group teams with customers to develop prototypes and production items in medical, manufacturing, and scientific instrument sectors.

All products are custom manufactured to meet customer needs and specifications, including DFARS and RoHS compliance. These quick-turn, cost-effective, low tooling cost processes offer excellent production alternatives to traditional fabrication methods for metal parts in high volumes and prototyping.